- Brand: TECHAMOR;

- Style: modern;

- Power Source: Battery Powered;

- Color: Yellow;

- Product Dimensions: 1.2"D x 2.8"W x 14.6"H;

- Item Weight: 8.8 Ounces;

- Alarm :Audible, Visual;

- Operating Humidity: 95 percent;

- Sensor Type: Semiconductor;

- Material: Plastic;

Y201 Gas Detector

- Details

- Video

Techamor Y201 Gas Leak Detector, Portable Methane Propane Combustible Natural Gas Leak Sniffer Detector

About this item

● Detect Various Flammable Gases: Portable Natural gas sniffer and tester is used to locate exact gas leak for various combustible gas, such as methane, natural gas, propane, LPG, sewer gas, coal gas, gasoline, other flammable gases.

● Detection Range: Approximately 50 to 10,000 ppm (Based on Methane), instant response once encounter leakage points.

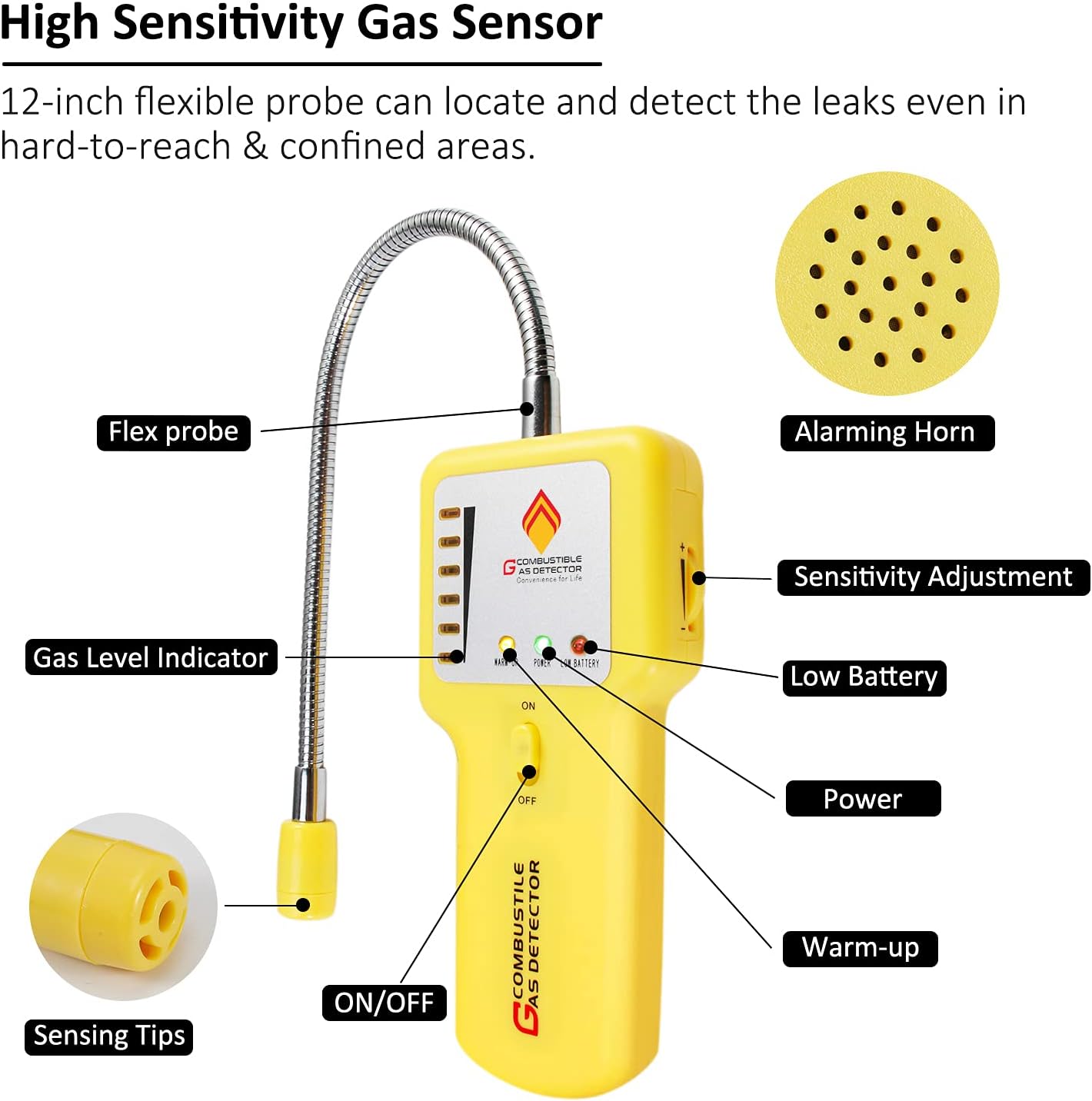

● Easy-to-Use Gas Leak Detector: Powered by 3 AAA batteries, 12 inch bendable gooseneck can locate and detect the gas leaks even in hard-to-reach areas at home & RV, kitchen and fireplace etc., refer to “How and Where to Use the Y201 Combustible Gas Detector” video.

● Sound and Visual Gas Alarm: UL2075 Certified. Six red LED’s (visual) and 85dB audible alerts once encounter gas leakage along pipeline or around the suspected leakage points.

● Original Design and Lifetime Technical Support: Design patent and certifications are applied to make sure the product quality and uniqueness. Replacement and friendly customer service are available even it’s broken in 24 months.

Product Description

Techamor Portable Gas Leak Detector/Sniffer – Y201

1. Where to use: Locate gas leak point at home & VR

The Y201 portable sniffer is an easy-to-use device that provides sound and visual alarm in presence of methane, propane, such as LPG, fuel and natural gas.

It’s mainly used to find and locate exact gas leak point along gas pipeline, around fittings or connectors at home & VR, and other similar applications. Helps to save hundreds of diagnostic fees from technician or plumber, and makes it’s possible to debug gas leakage anytime by DIY.

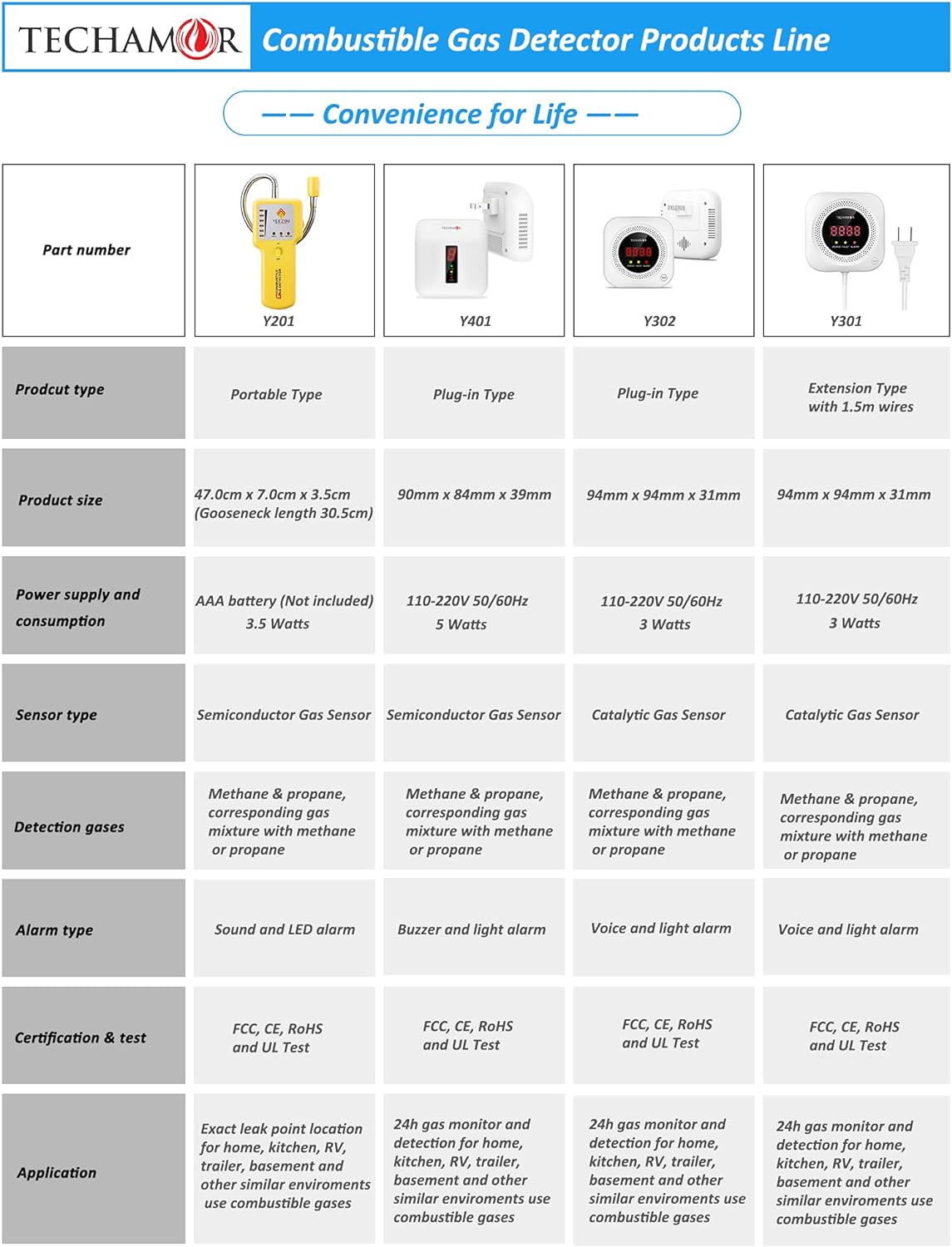

For 24h gas monitor and detection, refer to Y301 and Y302.

- Package Contains:

- 1*Gas Leak Detector

- 1*User Manual

- 1*Product Card

- 3*AAA Batteries

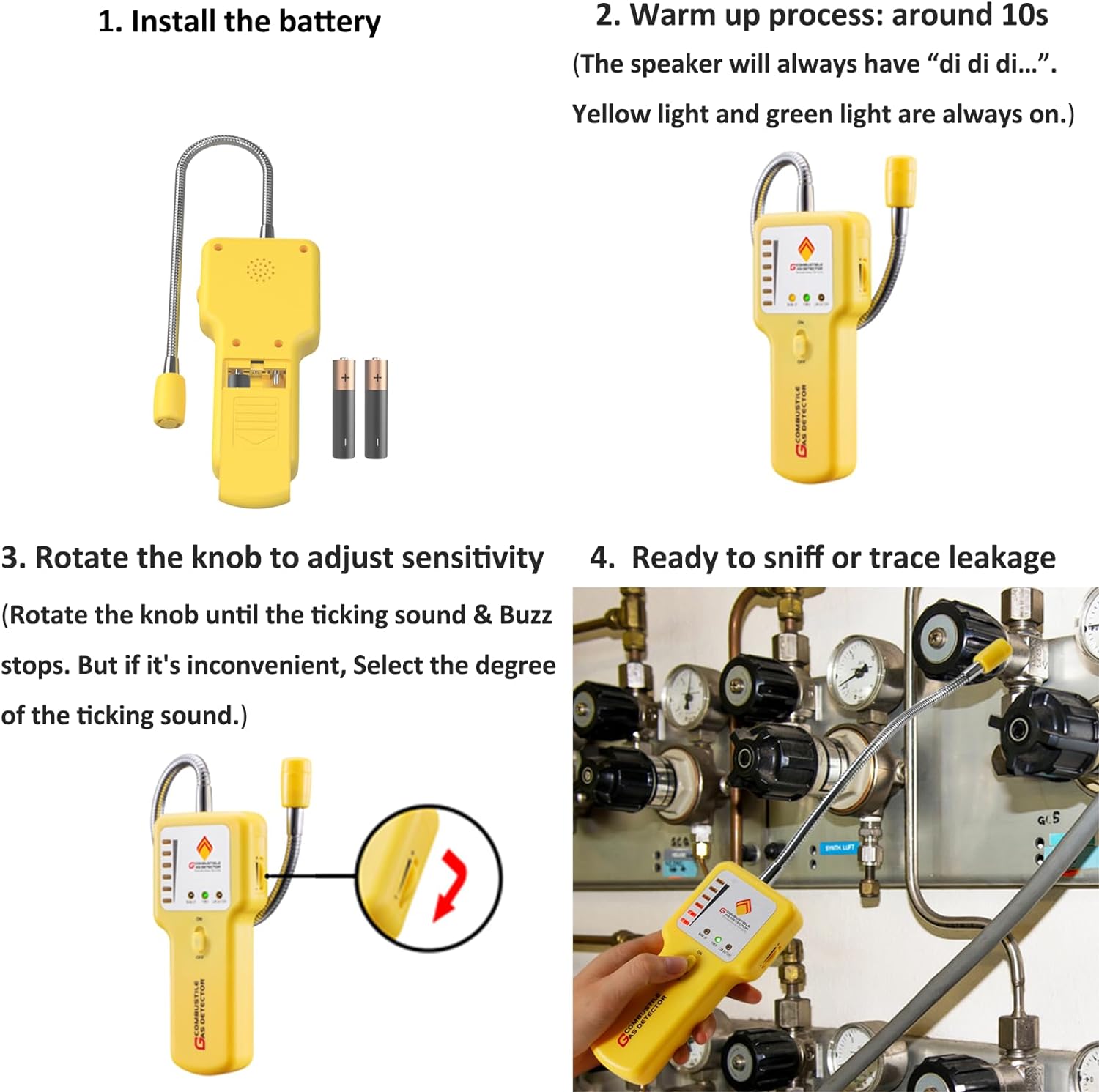

2. How to use: most important steps/tips – Sensitivity Adjustment

2.1 Warm up process: around 10~30s

The speaker will always have “di didi…” until we turn off device, except one moment in step 2.2. At warm up period, ticking noise frequency is slow: around 2~3 times/s.

The knob is used to adjust sensitivity of detector after finish 10s~30s warm up process, during the process, no matter how to adjust the knob, the device won’t have any reactions.

2.2 Rotate the knob to adjust sensitivity

If the alarm sounds prematurely and LED lights are on after warm up, need to decrease sensitivity to prevent false alarm (dial downward “-“, shown as red arrow) .

Rotate the knob to adjust sensitivity until the first bottom LED turn off or at the threshold of lighting up, and the moment that ticking sound stops. This is the best status.

But if it’s inconvenient to get the best status, we can just make the first bottom LED be on and have slow ticking “di di….” sound. Because once encounter leakage, all the rest 4~5 LED will be triggered on together at just one moment.

2.3 Ready to sniff or trace leakage

Move the probe along pipeline or around the suspected leakage points, such as fittings, connectors and switches, once encounter gas leakage, all 5~6 LED lights will be triggered immediately and the low frequency (2~3 times/s) ticking will change into piercing sounds (frequency 6~7 times/s, too fast and human ears cannot distinguish one time by one time) .

3. Different Usage Pictures Collection from Lovely Customers

4. Frequently asked questions and concerns:

4.1 Why always has ticking sound?

The design of ticking sound has two purposes: 1) Indicates the device is working.For some cases, we need to extend the probe to the area that we can’t see LED lights, customers could judge thru the sound changes. The green power LED light is also used to indicate the device is working. 2) Represent different levels of gas leakage. Low frequency (around 2~3 times/s) means warm-up period or no leakage, if changed into high frequency (around 6~7 times/s) during detection process, means encounter leakage issue.

Notes: above is based on we set sensitivity well, because if we rotate the knob at anti-clockside too much, even there don’t have any leakage, all the 6 LED will be triggered on and sound will become piecing high frequency.

4.2 Is it normal or safe if get 1 red bar when move to high moisture room, around connectors or simply blow on probe?

Don’t worry, it’s normal, the large moisture change and CO affect the sensor performance, and may lead to false alarm by 1~2 LED red bars, but only last for 1~3s (very short time) if we move probe away. If we encounter leakage along the pipeline or connectors, all 5~6 LED bars will be triggered on at one moment, light and piercing sound alarm will last at least for 6~8s.

4.3 what’s best distance between probe and pipeline/ranges/connectors…. during check process?

Recommend 1~10cm, if too far, concentration will become smaller as distance increase from leak point, and maybe not enough find and locate tiny leakage.

4.4 How about bubble method to check leakage compared with Y201?

Bubble is very good way and can be used to check all kinds of gas leakage while Y201 is mainly used for combustible gas. But for very tiny leakage and very strong leakage, bubble method maybe not good enough: 1) too tiny leak can’t blow up bubble, too strong will blow the liquid away and can’t have bubble, 2) some areas we can’t extend to apply bubble liquid, 3) need good luck and skills to control the bubble liquid concentration if DIY bubble liquid, 4) in some case, liquid contact may lead to equipment or device damage.

The best way is: use both methods for double confirm if allowed, since bubble is more visible.

Technical Details

| Alarm | Visual: 6 red LEDs, Audible: variable speed ticking |

| Response Time | ≤ 2 seconds (10% LEL, Lower Explosive Limit) |

| Warm up Time | Around 10 seconds |

| Resolution | 50 ppm |

| Batteries Required? | Yes, AAA batteries, 3 pcs |

| Battery Life | Approximately 15 minutes to 4 hours (Large difference between different battery brands according to experiments data in the lab) |

| Operating Temperature | 0 ~55 ℃ (32℉~131℉) |

| Relative Humidity | ≤ 95% to avoid condensation |

| Color | Yellow |

| Size | 14.6”x 2.8”x1.2” (37.0cm x 7.0cm x 3.2cm), housing material: plastic |